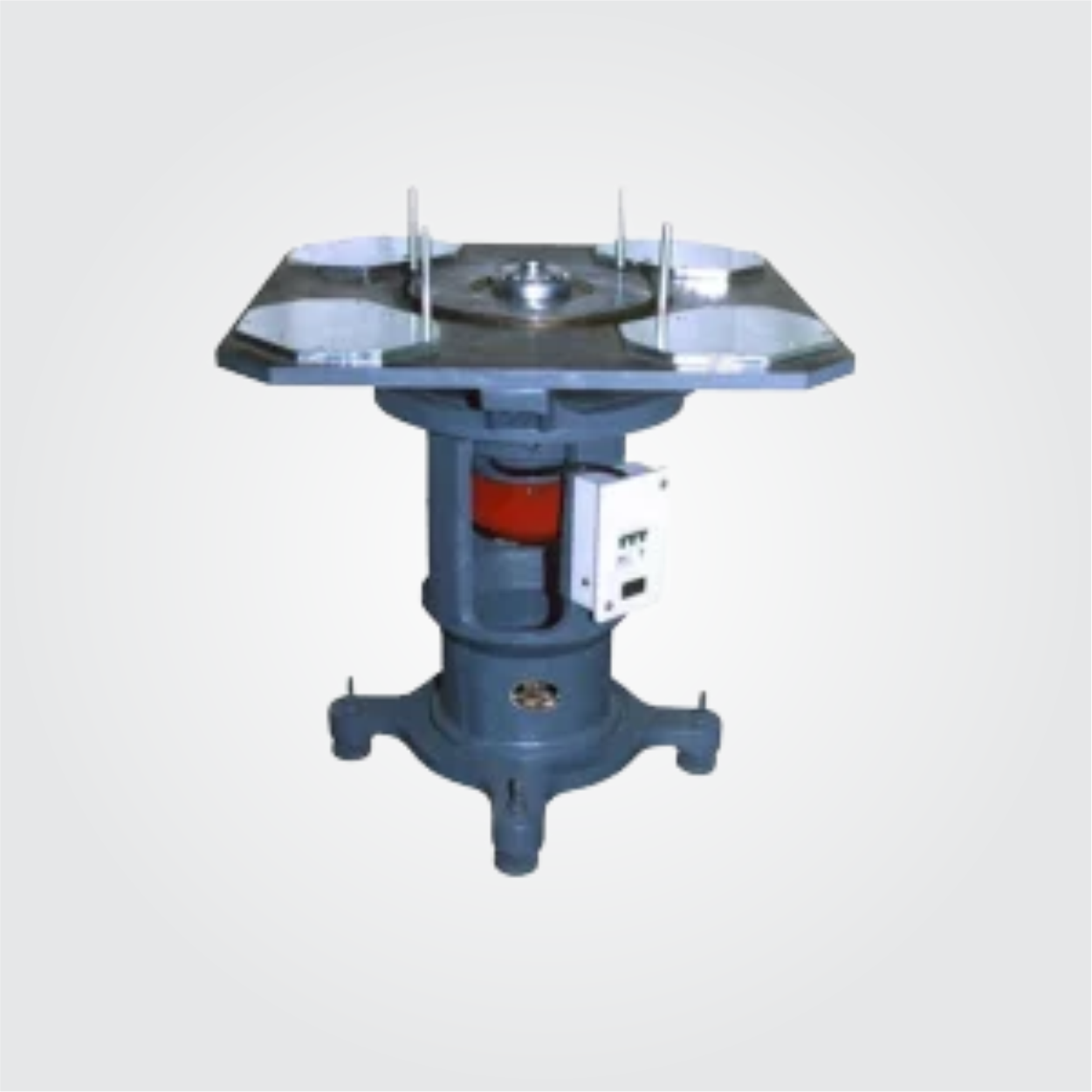

Diamond Polishing Machine

A diamond polishing machine is a specialized tool used in the diamond cutting and polishing industry to shape, grind, and polish rough diamonds into polished gemstones. Diamond polishing machines use diamond abrasives to cut and shape the diamonds, and the process involves several stages of grinding and polishing to achieve the desired shape, size, and finish.

Diamond polishing machines can vary in size and complexity, from small handheld machines used by individual diamond cutters to large industrial machines used in diamond cutting and polishing factories. They may be manual, semi-automatic, or fully automatic, depending on the level of precision and automation required for the specific application.

The process of diamond polishing typically involves several stages, including shaping, faceting, and polishing. In the shaping stage, the rough diamond is cut into a basic shape using diamond saw blades or diamond impregnated wire. In the faceting stage, the diamond is ground and shaped into a specific faceted shape using diamond grinding wheels. Finally, in the polishing stage, the diamond is polished to a high shine using diamond polishing wheels or pads.

Diamond polishing machines are designed to handle the unique properties of diamonds, which are among the hardest materials on earth. They must be able to withstand the high pressures and temperatures generated by the diamond cutting and polishing process, as well as the abrasive properties of the diamond itself.

Overall, diamond polishing machines play a critical role in the diamond cutting and polishing industry, allowing rough diamonds to be transformed into beautiful and valuable gemstones. They require a high degree of precision and expertise to operate, and they are essential tools in the production of high-quality diamonds for use in jewelry and other applications.

Inquire Now